Your current location: Home > APPLICATIONS

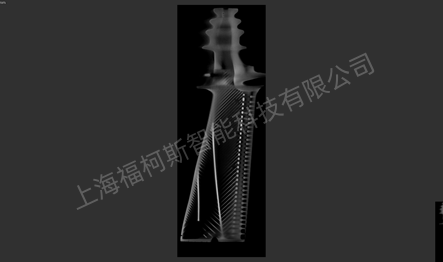

Industrial CT scanning of hollow turbine blades in aerospace engines allows for the detection of internal voids, calculation of the size and position of each void, and the pseudo-color display of defect sizes. With the Fiber Composite Material Analysis module, industrial CT can inspect coils in aircraft engines. It displays the winding direction of the coils through color-coding, providing users with a clear view of the winding technique employed during manufacturing.

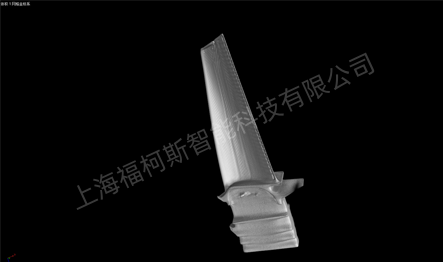

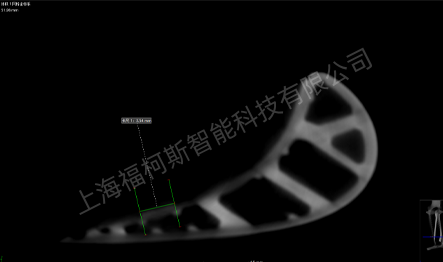

Using the Thickness Analysis module, industrial CT scans can measure the thickness of aircraft engine or turbine blades. It can identify areas with insufficient or excessive wall thickness or gap width within voxel, point cloud, mesh, or CAD datasets and color-code them to represent the wall thickness throughout different sections of the dataset.

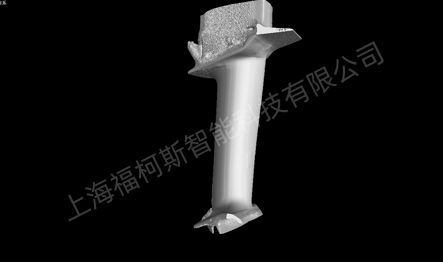

The Three-Dimensional Coordinate Measurement module in industrial CT allows for the measurement of individual components of aircraft engines.

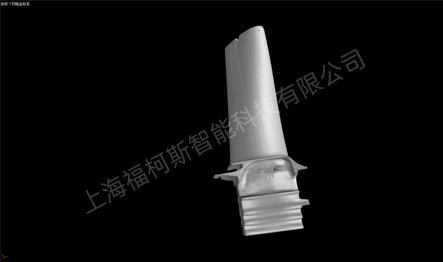

Industrial CT can be used during the production of items like rockets and aircraft to inspect anisotropic, layered composite materials, landing gear, and aviation pipeline weld seams, among other things.

Image display

Recommended Machine

- service@focus-sh.net

- (086) 021-31019175

- Room 102, Building 1, No.18, Handu Rd., Pudong New Area, Shanghai

Copyright © 2023 上海福柯斯智能科技有限公司 All Rights Reserved. 沪ICP备2023025604号-1