Your current location: Home > APPLICATIONS

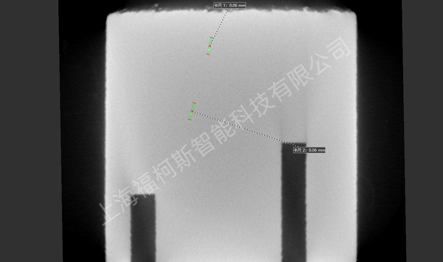

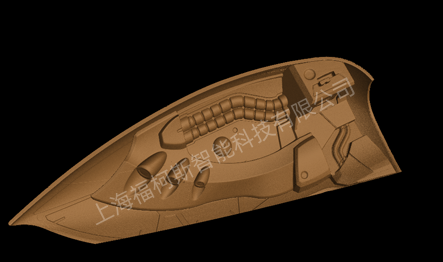

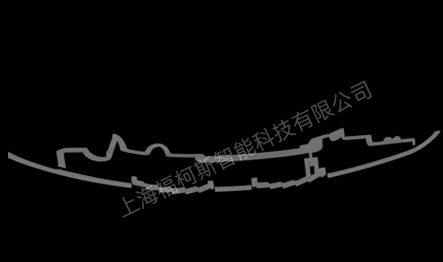

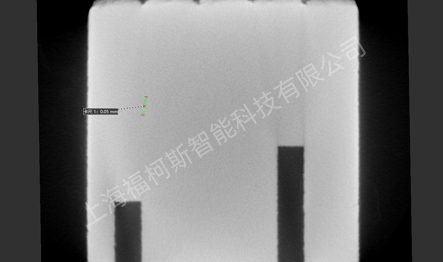

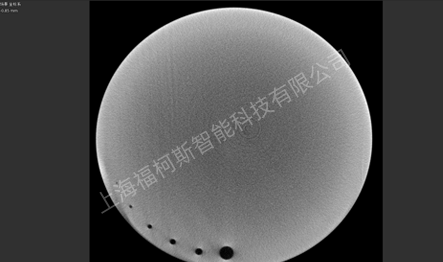

Utilizing specialized software, Industrial CT can model both the internal and external geometric features of a component. This technology enables precise measurement of feature dimensions and evaluates form and position tolerances. This insight assists clients in achieving a comprehensive understanding of any component defects, facilitating timely adjustments to design and production techniques to meet quality objectives.

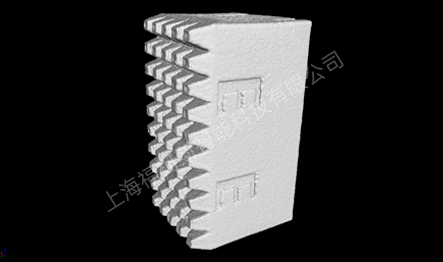

Moreover, Industrial CT can detect certain defects inherent to the PBD (powder bed fusion), such as porosity, lack of fusion, balling (attributed to the surface tension of molten metal), excessive surface roughness, and microscopic structural issues. Additionally, it can inspect structures within parts produced by additive manufacturing, including variations in density, embedded features, organic component design, dissimilar metals or materials, and surface finish quality.

Image display

Recommended Machine

- service@focus-sh.net

- (086) 021-31019175

- Room 102, Building 1, No.18, Handu Rd., Pudong New Area, Shanghai

Copyright © 2023 上海福柯斯智能科技有限公司 All Rights Reserved. 沪ICP备2023025604号-1